Drilling equipment for water wells involves understanding different rig types, their components, and essential safety gear. Choosing the right setup ensures efficient and safe well construction for reliable water access.

Tired of worrying about your water supply? Digging your own well can seem like a huge task, especially when you don’t know where to start with the tools. It’s easy to feel overwhelmed by all the different drilling equipment out there. Think of it like choosing the right bat for a game – you need the right gear for the job! We’re going to break down exactly what you need, from the giant drilling rigs to the small but mighty accessories, making sure you feel confident and prepared.

This guide will walk you through the essential drilling equipment for water wells, explaining what each piece does and why it’s important. We’ll cover everything from the main drilling machines to the safety gear that keeps everyone protected. Get ready to understand the world of well drilling like a pro, so you can get that fresh water flowing!

Understanding Water Well Drilling Equipment: A Beginner’s Deep Dive

Drilling a water well is a crucial step for securing a reliable water source, whether for a home, farm, or business. The equipment used is as diverse as the geological formations you might encounter. For beginners, it’s essential to grasp the basic categories and specific tools involved. Think of this as your starter kit for understanding the machinery that brings water from the earth to your tap.

The process relies on specialized drilling rigs, each designed for different ground conditions and depths. Alongside the rig, a host of accessories and safety measures are paramount. We’ll explore these components and provide a clear picture of what goes into drilling a water well efficiently and safely.

Types of Drilling Rigs for Water Wells

The heart of any water well drilling operation is the drilling rig. The type of rig chosen depends heavily on the soil and rock conditions, the required depth of the well, and the accessibility of the drill site. Understanding these differences is key to appreciating the scope of equipment needed.

1. Rotary Rigs

Rotary drilling is the most common method for water wells today. These rigs use a rotating drill bit to grind away rock and soil. A circulating fluid (drilling mud or water) is used to cool the bit, lubricate the hole, and carry the cuttings to the surface. Rotary rigs can be further categorized:

- Direct Rotary Rigs: These rigs use a pump to circulate drilling fluid down through the drill string and back up the annulus (the space between the drill string and the borehole wall).

- Reverse Circulation Rigs: In this method, the drilling fluid and cuttings are pumped up through the hollow drill pipe. This is often used in unconsolidated formations and can provide cleaner samples.

2. Cable Tool Rigs (Churn Drills)

These are among the oldest types of drilling rigs. They operate by repeatedly lifting and dropping a heavy, sharp-edged tool (a bit) that pulverizes the rock and soil. Spudding action, along with water, helps to create a slurry that is then bailed out of the hole. Cable tool rigs are slower and less efficient than rotary rigs for deep wells but can be effective in certain consolidated formations and are often simpler to operate.

In the US, the EPA provides guidelines for well construction to protect drinking water sources. You can find more information on their private well water page.

3. Truck-Mounted Rigs

Most modern water well drilling operations utilize truck-mounted rigs. These are powerful, versatile machines built onto a heavy-duty truck chassis. This mobility allows them to be easily transported to various job sites. They can be equipped with either rotary or cable tool drilling systems.

4. Skid-Mounted Rigs

Skid-mounted rigs are mounted on a trailer or skid and are typically smaller and lighter than truck-mounted rigs. They are ideal for areas with limited access or where a full-sized truck cannot go. They are often used for shallower wells or in confined spaces.

5. Augering Rigs

Auger rigs use a large, screw-like bit to bore into the ground. They are very effective in soft soil and clay but are generally limited to shallower depths and softer formations. They are not typically used for drilling deep water wells through hard rock.

Core Components of Drilling Equipment

Beyond the rig itself, numerous components work together to complete the drilling process. Understanding these parts helps in appreciating the complexity and the need for specialized knowledge.

1. The Drill Rig Power Unit

This is the engine that drives the rig. It can be diesel, gasoline, or electric, depending on the rig’s size and intended use. The power unit drives the rotary table, drawworks, pumps, and other essential functions.

2. Drill String

This is the assembly of pipes that transmits rotational force and weight to the drill bit. It consists of:

- Drill Pipe: Sections of steel pipe connected together to form the drill string.

- Drill Collars: Heavy-walled pipe joints that add weight to the bit, helping it to penetrate.

- Kelly Bar (for rotary rigs): A hex-shaped bar that connects the rotary motion from the rotary table to the drill string, allowing it to rotate.

- Top Drive (on newer rigs): An alternative to the Kelly bar, the top drive rotates the drill string directly from above, offering better control and efficiency.

3. Drill Bits

The “business end” of the drill string, the bit does the actual cutting or breaking of the ground. There are many types, each suited for different geological conditions:

- Roller Cone Bits: Used in rotary drilling, these bits have one or more cones with teeth that mill or crush the formation as they rotate. Different tooth designs (e.g., milled tooth, tungsten carbide insert) are for various rock types.

- PDC (Polycrystalline Diamond Compact) Bits: These bits have synthetic diamond cutters and are excellent for drilling through medium to hard rock formations at high speeds.

- Drag Bits: Used primarily in softer formations like clay or unconsolidated sands, these bits have blades or “wings” that cut or scrape the formation.

- Auger Bits: Used with auger rigs, these spiral bits bore into the soil.

- Cable Tool Bits: Specially shaped chisels and bits for churn drilling that break up rock.

4. Circulation System

This system is vital for removing cuttings and maintaining borehole stability. It includes:

- Mud Pump: Circulates drilling fluid (mud or water) down the drill string and back up the annulus.

- Water Tank/Mixing Tank: Holds the water or drilling fluid.

- Shale Shaker/Solids Control Equipment: Removes rock cuttings from the drilling fluid so it can be reused.

5. Hoisting System (Drawworks)

This mechanism, powered by the rig’s engine, is used to control the raising and lowering of the drill string and other heavy components into and out of the borehole. It includes the drum where the wire rope is wound, the motor, and controls.

6. Casing and Wellhead Equipment

Once the hole is drilled, casing is installed to prevent the borehole from collapsing and to isolate different water-bearing zones. This includes:

- Steel Casing: Durable pipe that lines the well.

- PVC Casing: Often used for shallower wells or screens.

- Centralizers: Devices that ensure the casing is centered in the borehole for proper cementing.

- Cementing Equipment: Used to secure the casing in place and prevent contamination.

- Wellhead: The surface assembly that seals the top of the casing, usually including a cap, vault, or pump connection.

Essential Supporting Equipment

Drilling a water well isn’t just about the rig. A variety of supporting tools and equipment are crucial for the entire operation to run smoothly and safely.

1. Air Compressors

For certain types of drilling (like air-rotary or DTH – Down-The-Hole hammer drilling), powerful air compressors are needed to provide the compressed air that drives the hammers and clears the hole.

2. Water Trucks and Delivery Systems

Water is essential for drilling operations, especially for creating drilling mud and cooling the bit. Water trucks, tanks, and pumps are often used to supply the necessary water to the drill site.

3. Generators

On-site power may be needed for pumps, lights, and other auxiliary equipment, especially if the site isn’t connected to electricity. Generators provide this essential power.

4. Tool Handlers and Catwalks

These are structures that facilitate the safe handling and connection/disconnection of heavy drill pipe sections. They improve efficiency and reduce the risk of injury during pipe management.

5. Water Well Pumps and Well Screens/Filters

While not part of the drilling equipment, these are integral to the completed well. Well screens (or well points) are placed downhole to filter out sediment while allowing water to enter. Pumps are then installed to bring the water to the surface. For more on well construction standards, the National Ground Water Association (NGWA) is an excellent resource.

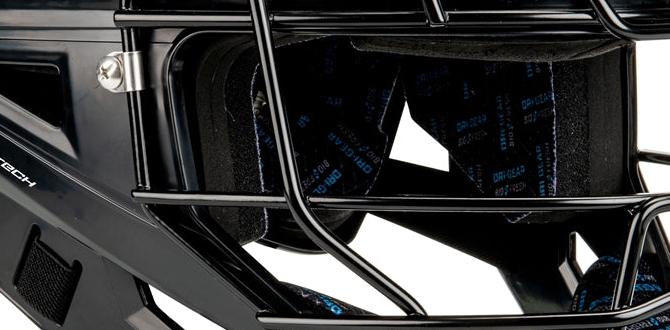

Safety Equipment: Non-Negotiable for Well Drilling

The drilling environment can be hazardous. Proper safety equipment is not just recommended; it’s mandatory for protecting personnel. This aspect of well drilling equipment is as critical as the drilling rig itself.

1. Personal Protective Equipment (PPE)

- Hard Hats: To protect against falling objects.

- Safety Glasses/Goggles: To protect eyes from dust, debris, and fluids.

- Gloves: Heavy-duty, durable gloves for handling pipes and equipment, protecting against cuts, abrasions, and chemical exposure.

- Steel-Toed Boots: To protect feet from heavy equipment and dropped objects.

- Hearing Protection: Earplugs or earmuffs to protect against the noise generated by drilling operations.

- High-Visibility Clothing: To ensure workers are easily seen by equipment operators, especially in low light or active areas.

- Respirators: May be needed to protect against dust, silica, or other airborne particulate matter.

2. Rig Safety Features

- Guards and Shields: On all moving parts of the rig (pulleys, chains, belts) to prevent entanglement.

- Fire Extinguishers: Readily accessible and appropriate for potential fuel or electrical fires.

- First Aid Kit: Fully stocked and easily accessible on site.

- Emergency Shut-off Switches: Clearly marked and functional for the power unit and other critical machinery.

3. Site Safety

- Barricades and Warning Signs: To keep unauthorized personnel away from the active drilling area.

- Proper Lighting: For night operations or low-light conditions.

- Fall Protection: Harnesses and lanyards for working at heights on the rig.

Maintenance and Tools

Well drilling equipment is heavy-duty machinery that requires regular maintenance and a good set of hand and power tools for repairs and adjustments.

1. Lubrication Systems

Grease guns, oil cans, and proper lubricants are essential for maintaining the moving parts of the rig, reducing wear and tear.

2. Hand Tools

- Wrenches (pipe wrenches, adjustable wrenches, sockets)

- Screwdrivers

- Pliers

- Hammers

- Measuring Tapes

3. Power Tools

- Impact Wrenches (for connecting/disconnecting pipe joints)

- Grinders

- Drills

4. Specialized Tools

- Pipe Elevators/Spiders: Used to lift and hold heavy sections of casing and drill pipe.

- Tong Bits: Specialized inserts for pipe wrenches (tongs) to grip drill pipe without damaging it.

- Torque Wrenches: To ensure pipe connections are tightened to the correct specifications.

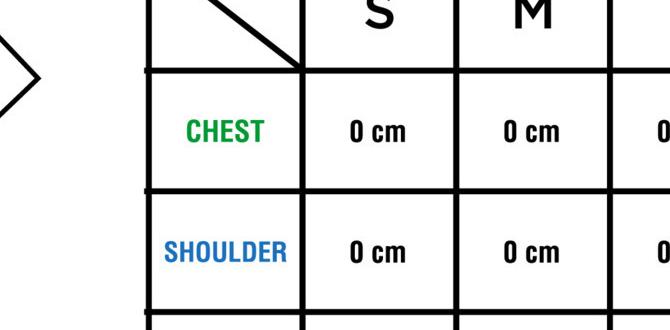

Table: Comparing Common Drill Bit Types

Choosing the right drill bit can significantly impact drilling speed, efficiency, and cost.

| Drill Bit Type | Best For Formations | Pros | Cons |

|---|---|---|---|

| Roller Cone (Milled Tooth) | Soft to Medium Rock | Cost-effective for softer formations, good penetration rate. | Can wear down quickly in abrasive formations. |

| Roller Cone (Tungsten Carbide Insert – TCI) | Medium to Hard Rock | More durable than milled tooth, penetrates harder rock efficiently. | Higher initial cost. |

| PDC | Medium to Very Hard Rock, Shales | High ROP (Rate of Penetration), good durability in specific formations, excellent for directional drilling. | Can be damaged by intermittent drilling or hard, abrasive formations. |

| Drag Bits | Soft Sediments, Clay, Sand | Inexpensive, high ROP in soft material. | Not suitable for rock, can get stuck in unstable formations. |

Environmental Considerations and Regulations

Drilling for water involves federal and local regulations designed to protect groundwater resources and ensure public safety. Understanding these is part of responsible equipment selection and operation.

Proper disposal of drilling fluids and cuttings is crucial. Regulations often require specific methods to prevent contamination of soil and water bodies. This can influence the choice of drilling method and associated equipment, such as solids control systems on rotary rigs.

The U.S. Geological Survey (USGS) provides extensive data and guidance on groundwater resources and well construction across the country. Their groundwater and wells section is a valuable resource for understanding the science behind well drilling and its impact.

Furthermore, site remediation and well abandonment (when a well is no longer in use) are heavily regulated to prevent groundwater contamination. The equipment used for these tasks also falls under the umbrella of well drilling gear.

Cost Factors for Drilling Equipment

The acquisition of well drilling equipment represents a significant investment. Costs can vary dramatically based on:

- Rig Type and Size: Larger, more powerful, truck-mounted rotary rigs capable of drilling deep wells cost significantly more than smaller skid-mounted or truck-mounted rigs for shallower wells.

- Brand and New vs. Used: Reputable brands often come with a higher price tag, but also with better durability and support. Used equipment can offer substantial savings but carries the risk of wear and tear an unknown maintenance history.

- Features and Technology: Rigs with advanced features like top drives, automated pipe handling, or sophisticated monitoring systems will be more expensive.

- Attachments and Accessories: The cost multiplies when you consider the variety of drill bits, pumps, tanks, and specialized tools required.

- Maintenance and Operating Costs: Fuel, spare parts, and skilled labor for operation and maintenance are ongoing expenses that must be factored in.

For those looking to start a well drilling business or undertake a significant personal project involving multiple wells, leasing options might be a more financially viable starting point than outright purchase.

Frequently Asked Questions About Drilling Equipment for Water Wells

What is the most common type of rig used for water wells?

Rotary drilling rigs, particularly truck-mounted ones, are the most common for water wells due to their efficiency and versatility in various geological conditions.

Do I need specialized training to operate well drilling equipment?

Yes, operating heavy drilling equipment requires significant training, experience, and knowledge of safety protocols and geological conditions to do it safely and effectively.

How much does water well drilling equipment typically cost?

Costs vary widely. A small, used skid-mounted rig might be a few thousand dollars, while a new, large truck-mounted rotary rig with all accessories can cost hundreds of thousands of dollars.

What is the difference between a drill bit and a drill head?

A drill bit is the cutting or grinding component at the end of the drill string. The “drill head” is often used interchangeably with drill bit, or it can refer to the entire assembly at the end of the drill string, including the bit and any associated stabilizers.

What is drilling mud and why is it used?

Drilling mud is a specially formulated fluid (often clay and water) circulated during rotary drilling. It cools and lubricates the bit, carries rock cuttings to the surface, stabilizes the borehole walls, and controls subsurface pressures.

Can I rent water well drilling equipment?

Yes