Get the perfect fit for your EvoShield catchers leg guards with custom molding. Discover how to make them feel like they’re part of you for ultimate comfort and protection.

Catching is demanding. Your gear needs to keep up! EvoShield catchers leg guards are top-notch, but their magic really happens when they fit you perfectly. A guard that’s too loose or too tight can be distracting and even risky. You want guards that feel like a second skin, moving with you, not against you. We’ll walk through how to get that custom, molded fit that lets you focus on blocking pitches and throwing runners out, instead of on your equipment. Ready to make your leg guards truly yours? Let’s dive in!

Why a Custom Fit for EvoShield Leg Guards Matters

As a baseball player, especially a catcher, your gear is your armor. When it comes to EvoShield catchers leg guards, the “customization” isn’t about altering the material in a factory. Instead, it’s about their innovative Gel-to-Shell™ technology that allows you to mold them precisely to your body. This process is crucial for several reasons, impacting your performance, comfort, and safety on the field.

Think about it: you’re in a squatting, twisting, and lunging position for hours. If your leg guards aren’t fitting right, they can:

- Restrict Movement: Guards that are too bulky or don’t conform to your leg can make it harder to get into your stance, block pitches effectively, or throw runners out.

- Cause Discomfort: Rubbing, pinching, or pressure points from ill-fitting guards can be incredibly distracting and painful, taking your focus away from the game.

- Reduce Protection: If a guard shifts, it leaves areas exposed. A custom fit ensures the protective padding stays exactly where it’s supposed to be, offering reliable impact absorption.

- Affect Endurance: Uncomfortable gear makes you tired faster. When your equipment works with you, you can play harder for longer.

EvoShield’s approach to personalized protection is what sets their catchers leg guards apart. It’s designed to give you the confidence that your gear is working as hard as you are, right from the first pitch.

Understanding EvoShield’s Gel-to-Shell™ Technology

Before you start molding, it’s helpful to know what’s happening. EvoShield’s core innovation is their Gel-to-Shell™ technology. This isn’t just a fancy name; it’s a scientific process that hardens upon exposure to air, creating a protective shield that is custom-molded to your body.

Here’s the breakdown:

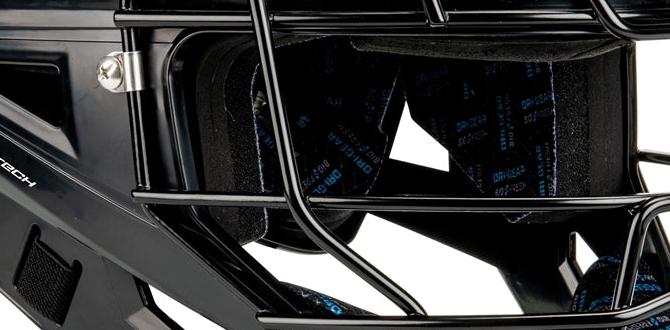

- The Gel Pack: Your EvoShield leg guards come with a small, sealed packet containing a soft, pliable gel. This gel is the “magic” ingredient.

- Activation: When you open the sealed packet, the gel is exposed to air. This exposure triggers a chemical reaction, and the gel begins to harden.

- Molding Process: While the gel is still soft and pliable (but not wet!), you strategically place it against your leg. The gel then takes the exact shape of your leg, ankle, and shin.

- Shield Formation: Within minutes, the gel hardens into a custom-molded shield. This shield is then permanently shaped to your unique anatomy.

- Integration: The hardened shield is sewn into or attached to the fabric of your leg guard, providing a rigid, protective layer that fits like a glove.

The beauty of this technology is that it simplifies the process of getting professional-level custom protection. You don’t need a special heat machine or a professional fitter (though they can help if you prefer!). You can achieve this precise fit in the comfort of your own home.

Step-by-Step Guide to Customizing Your EvoShield Catchers Leg Guards

Getting that perfect, custom fit for your EvoShield catchers leg guards is straightforward. Follow these steps carefully, and you’ll have guards that feel like they were made just for you.

Step 1: Gather Your Supplies

Before you begin the molding process, make sure you have everything ready. This ensures a smooth and efficient session.

- Your EvoShield Catchers Leg Guards: Make sure they are the correct size for your leg.

- The Gel-to-Shell™ Activation Packets: These come with your leg guards.

- A Flat, Clean Surface: You’ll need space to lay out your leg guards and work.

- A Pair of Scissors: To open the activation packets.

- A Towel or Cloth: To wipe any residual moisture from your hands or legs, if needed.

- A Comfortable Place to Sit: You’ll need to be able to position your leg comfortably during the molding.

Step 2: Prepare Your Workspace and Yourself

A little preparation goes a long way.

- Find a spot where you won’t be interrupted.

- Ensure the area is clean and free of dust or debris.

- Wash and dry your hands thoroughly.

- Have someone help you if possible, especially for the first time. An extra pair of hands can ensure you position everything correctly.

Step 3: Position the Leg Guard

It’s time to get the leg guard ready to be molded.

- Put on the leg guard as you normally would, but don’t secure all the straps too tightly yet. You want it snug, but not so tight that it restricts blood flow or makes it difficult to position afterward.

- Ensure the leg guard is positioned correctly on your shin and knee. The knee cap should align with the knee pad, and the lower part should cover your ankle and instep appropriately.

- Make sure the fabric of the leg guard is as smooth and wrinkle-free against your leg as possible.

Pro Tip: Wear the athletic socks you normally wear when playing baseball. This ensures the molding accounts for the fabric thickness. If you wear different types of socks for games, consider molding with those.

Step 4: Prepare the Gel-to-Shell™ Shield

Now it’s time to activate the protective shield.

- Locate the Gel-to-Shell™ packet(s) that came with your leg guards. There will typically be one for the shin and one for the kneecap, or sometimes one larger one that covers both.

- Crucially: DO NOT open the packet until you are ready to apply it. The activation process begins immediately upon opening.

- Using scissors, carefully cut open one packet along the indicated line. The gel inside will be soft and pliable.

- Immediately after opening, gently squeeze the gel out of the packet. It will resemble a thick gel or a slightly sticky putty.

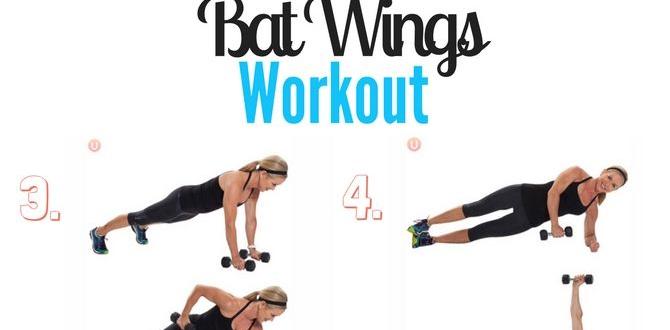

Step 5: Apply and Mold the Gel Shield

This is where the customization happens.

- Quickly and carefully place the gel onto the designated area of the leg guard that is already on your leg. You may need to spread it within the internal pocket or directly onto the fabric designated for the shield. Follow the specific instructions that came with your EvoShield model, as placement can vary slightly.

- Work Fast: You have a limited window of about 5-10 minutes before the gel starts to firm up.

- Press the gel firmly into place, ensuring it covers the intended area smoothly.

- Key Molding: Use your hands to gently shape the gel. Mold it to the contours of your shin, instep, and knee area. If you have someone helping, they can assist in pressing and shaping.

- Ensure the gel is evenly distributed and adheres well to the fabric. Avoid any major wrinkles or folds in the gel itself.

- If your leg guard has multiple molding points, repeat steps 4 and 5 for each packet.

Step 6: Secure and Let It Cure

The shield needs time to harden and form its protective shape.

- Once the gel is in place and molded, secure the leg guard straps snugly. This helps keep the gel in the correct position while it hardens.

- Leave the leg guard on for the recommended curing time. EvoShield typically recommends 20-30 minutes, but always check your product’s manual.

- During this curing time, try to remain as still as possible. Avoid unnecessary movements that could disrupt the molding process.

- Do not try to remove the leg guard prematurely.

Step 7: Final Assembly and Check

After the curing period, it’s time to see your custom fit.

- Carefully remove the leg guard.

- You will notice that the gel has hardened into a rigid, custom-shaped shield.

- Inspect the shield for any areas that might feel uncomfortable against your leg (though this is rare if molded correctly).

- If the shield is integrated into a fabric pocket, you may need to re-insert it or ensure it sits correctly. Some models have shields that are permanently attached after molding, while others might require you to slide them into place or secure with Velcro.

- Put the leg guard back on, securing the straps.

- Walk around, bend your knee, and simulate some catcher movements. The guard should feel secure, comfortable, and move naturally with your leg.

Important Note: The Gel-to-Shell™ process is permanent. Once molded, the shield cannot be un-molded or re-molded. So, take your time and ensure you are happy with the fit before the gel fully hardens.

Tables: Comparing Leg Guard Fit Issues

A great fit makes all the difference. Let’s look at what happens when things aren’t quite right.

Table 1: Common Leg Guard Fit Problems and Their Impact

| Problem | Description | Impact on Performance | Impact on Comfort | EvoShield’s Custom Fit Solution |

|---|---|---|---|---|

| Too Tight | Straps are cinched too much, or the guard is too small. | Restricts movement, hinders quick transitions, can make blocking difficult if it digs in. | Can cause numbness, chafing, and pressure marks. | Proper sizing combined with molding ensures a snug but not constricting fit. |

| Too Loose | Straps are not tight enough, or the guard is too large and shifts easily. | Guard can slide down or twist, leaving exposed areas and not protecting where needed. | Annoying distractions, potential for scrapes or impacts on unprotected areas. | Molding creates a form-fitting shield that stays in place. |

| Poor Knee Cap Alignment | Knee pad sits too high, too low, or too far to one side on the kneecap. | Reduced protection for the knee joint, potential for hard impacts directly on exposed bone. | Can cause discomfort or direct pressure on the knee. | Molding ensures the protective shield aligns perfectly with your knee anatomy. |

| Ankle Drag/Rub | The lower part of the guard interferes with foot movement or rubs the ankle. | Can affect agility, especially when moving side-to-side or coming out of the crouch. | Chafing, blisters, or general irritation around the ankle area. | Custom molding shapes the lower portion to your foot and ankle profile. |

| “Bulky” Feeling | Guard doesn’t conform to the leg, feels like an external object. | Can impede natural leg flexion and speed of adjustment. | Uncomfortable and a constant reminder of the gear. | The hardened shield is thin and contours precisely to your leg shape. |

Table 2: EvoShield Leg Guard Features and Benefits

| Feature | Benefit | Relevance to Custom Fit |

|---|---|---|

| Gel-to-Shell™ Technology | Air-activated hardening creates a custom-molded protective shield. | Directly provides the essential custom fit, ensuring superior protection and comfort. |

| Breathable Fabric | Keeps legs cooler and reduces sweat build-up during intense play. | Enhances overall comfort, allowing the custom-fit guard to feel less intrusive. |

| Adjustable Straps | Allow for initial snugness and fine-tuning of fit. | Crucial for ensuring the leg guard stays in place during the molding process. |

| Reinforced Padding | Provides additional cushioning in key impact zones. | Works in conjunction with the custom shield for maximum impact absorption. |

| Lightweight Design | Reduces fatigue and allows for greater agility. | Makes the custom-molded guard feel less cumbersome, enhancing natural movement. |

Tips for Optimal EvoShield Customization

While the process is designed to be simple, a few extra tips can ensure you get the best possible custom fit for your EvoShield catchers leg guards.

- Read the Manual: Always refer to the specific instructions that came with your EvoShield model. Designs can vary slightly.

- Environment Matters: While the Gel-to-Shell™ technology works in most conditions, avoid extremely cold temperatures, which can slow down the hardening process. Room temperature is ideal.

- Don’t Over-Apply Pressure: When molding, apply firm but gentle pressure. You’re shaping, not squashing.

- Uniform Application: Ensure the gel is spread evenly. Gaps or thick clumps can lead to uneven protection.

- Cleanliness: Make sure your hands and the inside of the leg guard are clean and dry before you start. Any dirt or moisture can interfere with the gel’s adhesion.

- Team Strategy: If you’re a coach or parent helping a young player, have them wear the equipment for a bit before molding. They can point out any immediate pressure spots they feel, allowing for minor adjustments before it cures.

- Patience is Key: While the molding process is quick, don’t rush the curing. Let the shield harden fully for optimal results.

- Single Mold: Remember, this is a one-time molding process. The Gel-to-Shell™ hardens permanently. Make sure you’re satisfied with the position before the 20-30 minutes are up.

When to Consider Professional Fitting

For most players, the DIY molding process for EvoShield catchers leg guards is effective and straightforward. However, there are situations where seeking professional assistance might be beneficial.

- Uncertainty and First-Timers: If you’re particularly nervous about the process or this is your first time molding gear, a professional can guide you through it, building your confidence.

- Complex Leg Anatomy: While rare, some players might have unique leg shapes or past injuries that make a standard molding difficult. A pro has experience with various anatomies.

- Team Equipment Orders: If you’re outfitting an entire team, especially a youth team, having a professional do it ensures consistency and proper application for all players. This saves time and ensures everyone gets a good fit.

- Seeking Expert Advice: Professionals who specialize in baseball equipment might offer insights into other aspects of your gear that could impact performance or comfort.

You can often find professional fitting services at larger sporting goods stores, specialized baseball equipment shops, or through local baseball academies. Don’t hesitate to ask store representatives where you purchased your gear if they offer or recommend fitting services.

Maintaining Your Molded EvoShield Leg Guards

Once you’ve achieved that perfect custom fit, proper care will ensure your EvoShield leg guards maintain their integrity and protection for seasons to come.

- Cleaning: After each use, wipe down the exterior of your leg guards with a damp cloth. This removes dirt, sweat, and grime. For the interior fabric, use a mild soap and water solution. Avoid harsh chemicals or abrasive cleaners, as they can damage the material.

- Drying: Always air dry your leg guards completely. Never put them in a dryer or expose them to direct heat, as this can warp or damage the protective shield and fabric. Lay them flat or hang them in a well-ventilated area away from direct sunlight.

- Storage: Store your leg guards in a cool, dry place. Avoid cramming them into tight spaces or placing heavy objects on top of them, which could compromise the molded shape. A dedicated gear bag or shelf is ideal.

- Check for Wear and Tear: Periodically inspect the straps, buckles, and fabric for any signs of excessive wear, tearing, or damage. If any component is failing, consider replacing it to maintain the guard’s effectiveness.

- The Shield Itself: The molded shield is designed to be durable, but it’s not indestructible. Avoid extreme impacts that could potentially crack or damage the shield beyond its protective capacity. EvoShield’s warranty information can be helpful if you encounter issues.

FAQ: Your EvoShield Customization Questions Answered

Here are answers