Have you ever wondered where baseballs are made for the major leagues? It’s a question many fans ask. Baseballs are more than just a round object; they’re a key part of the game. Imagine stepping up to the plate, gripping a fresh ball, and feeling the excitement in the air.

Most people think baseballs come from just anywhere. But they don’t! Each baseball is crafted with care. The majority are made in a special place in the United States. This factory is where the magic begins.

As you read this, think about the journey of a ball. From raw materials to the final product, it takes skill and precision. So, what makes these baseballs so special? Let’s dive into the world of baseball manufacturing and uncover some surprising facts!

Where Are Baseballs Made For The Major Leagues? Discover Their Origins!

Where Are Baseballs Made for the Major Leagues?

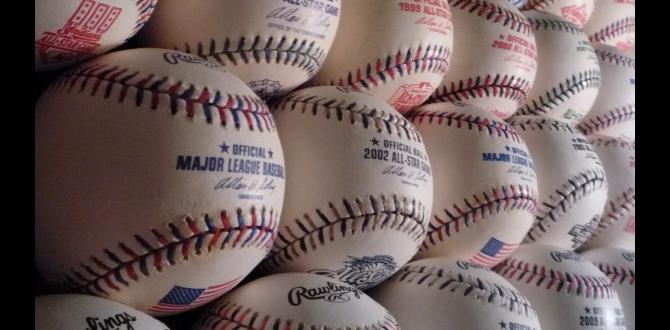

Most Major League Baseballs are made in a special factory in Costa Rica. This factory produces about a million baseballs each year. Each ball goes through a careful process to ensure quality. For example, workers hand-stitch leather around a rubber core. Did you know that a single baseball is used for only a few pitches in a game? Fans often wonder how these balls can be so durable. Understanding where baseballs are made adds to the excitement of the game!History of Major League Baseballs

Discuss the evolution of baseball manufacturing in the Major Leagues.. Highlight significant changes in materials and design over the years..Baseballs have come a long way since their early days. Originally made from various materials like leather and string, the design has changed significantly. In 1970, the modern baseball emerged, focusing on durability and performance. Today’s baseballs use a unique blend of rubber, yarn, and leather. This combination makes them more consistent and ready for home runs! The stitching? Still hand-sewn to ensure they fly straight, just like a perfect pitch. Let’s dive into the timeline of changes:

| Year | Material/Design Change |

|---|---|

| 1840s | First baseballs made with wool and leather. |

| 1930 | Introduction of the rubber core. |

| 1970 | Launch of the modern baseball design. |

This fun journey through time shows how the game adapts and evolves, keeping fans on their toes with every pitch!

Manufacturing Locations

Identify key factories producing Major League baseballs.. Explore geographic factors influencing baseball production..Major League baseballs are produced mainly in two U.S. factories: one in Costa Rica and another in Kentucky. Why those spots? The warm weather in Kentucky and the skilled workers in Costa Rica play a big role. They ensure that every baseball is well crafted, ready to be hit out of the park! Did you know it takes about 108 stitches to make a single baseball? It’s a real stitch-up! Here’s a quick look at these key factories:

| Factory Location | State/Country | Key Features |

|---|---|---|

| Rawlings | Kentucky, USA | High-quality materials and experienced workers. |

| Venezuela | Costa Rica | Warm climate and efficient production. |

Materials Used in Baseball Production

Detail the types of materials used in Major League baseballs, including leather and thread.. Explain the importance of quality and durability in material selection..Baseballs used in Major League games are made with a few key materials that pack a punch. The outer layer is leather, specifically high-quality cowhide. Underneath, you’ll find a tightly wound layer of thread that keeps everything together. This strong thread helps the ball maintain its shape and bounce, kind of like a well-packed burrito! Choosing the best materials is crucial. Durability ensures these balls can handle powerful pitches and swings without falling apart and keeps our baseball dreams alive!

| Material | Purpose |

|---|---|

| Leather | Outer cover for grip and durability |

| Polyester Thread | Secures the core and maintains shape |

| Cork and Rubber Core | Provides bounce and energy |

The Manufacturing Process

Outline each step in the production of a Major League baseball.. Highlight the technology and craftsmanship involved in the process..Making a Major League baseball is like baking a cake but with more steps! First, the core called the “pill” is made from rubber and wound tightly with yarn. Next, skilled workers wrap the pill in leather, making it look sharp and shiny. They use special tools to ensure the seams are perfect. The whole process blends craftsmanship and technology, ensuring each baseball is just right! Did you know over 1 million baseballs are made each season? That’s a lot of home runs waiting to happen!

| Step | Description |

|---|---|

| 1. Core Creation | Rubber and yarn form the inner core. |

| 2. Wrapping | Leather wraps around the wound core. |

| 3. Seam Inspection | Special tools check for perfect seams. |

Quality Control Procedures

Describe the quality checks and standards that Major League baseballs must meet.. Discuss how these procedures affect performance and longevity..Baseballs used in Major League games undergo strict quality checks. First, each ball must pass a test for weight, size, and bounce. This ensures they fly just right when hit. The stitching is also checked. If it’s off, the ball might as well join the “no-hitter” club! These processes help the balls last long and perform well. Without this care, pitchers and batters would be in for a surprise, and not the good kind!

| Quality Check | Standard |

|---|---|

| Weight | 5 ounces |

| Diameter | 9 inches |

| Bounce Test | Proper height |

Impact on Game Performance

Analyze how the manufacturing location and materials influence baseball performance.. Discuss player preferences regarding baseball specifications..The spot where baseballs are made can change how they perform in a big way. Different materials, like leather and yarn, can make a baseball feel bouncy or soft, affecting how players hit or throw. Some players swear by certain brands, claiming they can hit better with a specific ball. It’s like magic! Here’s a quick look at how the making location and materials stack up:

| Material | Impact on Performance |

|---|---|

| Leather | Durability and grip increase. |

| Yarn | Effects how the ball feels when thrown. |

| Cork Center | Generates better speed and distance. |

Players often have preferences that lead them to choose specific brands or types. This ensures they stay in the game, ready to hit a home run or catch that perfect pitch! After all, a good baseball is like your favorite snack—if it doesn’t taste right, nobody’s happy!

The Economics of Baseball Manufacturing

Examine the cost breakdown of producing Major League baseballs.. Discuss the impact of labor and production costs on the price of baseballs..The costs of making Major League baseballs include many important factors. First, there are materials used. The leather, yarn, and rubber cost money. Second, labor plays a big role. Workers craft the balls with skill. This adds to the total price. Third, machines help in production. They make each ball faster. Yet, machine upkeep can be expensive. Here’s a simple breakdown:

- Materials: 60%

- Labor: 25%

- Production costs: 15%

So, the next time you see a baseball, remember how much goes into making it!

Where are Major League baseballs made?

Major League baseballs are made in Costa Rica. They are produced in special factories to ensure quality and standard.

Environmental Considerations in Baseball Production

Explore sustainable practices in the manufacturing of baseballs.. Discuss the industry’s response to ecological concerns..Baseball production is becoming more eco-friendly. Many factories now use sustainable materials. This helps reduce waste and pollution. Companies are also recycling old baseballs into new products. The industry cares about the planet and wants to make a positive change. Here are some ways they are helping:

- Using organic leather and natural rubber.

- Reducing energy use in manufacturing.

- Finding eco-friendly packaging solutions.

These steps show a commitment to a cleaner environment.

How are baseball companies becoming more eco-friendly?

Baseball companies are changing to help the planet. They are using sustainable materials and cutting back on waste. The aim is to make baseball a greener sport.

Future Trends in Baseball Manufacturing

Predict upcoming changes in baseball manufacturing techniques.. Discuss potential innovations in materials and technology that could impact the sport..The future of baseball manufacturing looks exciting! New materials and technologies promise big changes. For example, manufacturers might use stronger and lighter materials. This could make baseballs last longer and perform better. Smart technology may enter the field too. Imagine baseballs with sensors that track speed and spin. Here are some ideas:

- Advanced materials for better durability

- Incorporation of data tracking technology

- Eco-friendly manufacturing processes

These shifts could change how players train and how fans enjoy the game. The future is bright for baseball!

What are the new materials being used for baseballs?

Manufacturers are exploring new synthetic materials that enhance performance. These materials can be lighter and more durable than traditional leather.

Conclusion

In conclusion, baseballs for the major leagues are primarily made in Costa Rica and the USA. These countries ensure quality and consistency. Now that you know where baseballs come from, you can look for a baseball made in these places. Research more about the manufacturing process to see how your favorite sport comes to life!FAQs

What Specific Facility Is Responsible For Manufacturing Baseballs Used In Major League Baseball (Mlb) Games?The facility that makes baseballs for Major League Baseball (MLB) is called Rawlings. They are located in Costa Rica. Rawlings makes millions of baseballs for the players every year. Each ball is carefully designed for games. Players trust these baseballs to help them win!

How Does The Production Process Of Mlb Baseballs Ensure Their Quality And Consistency?The production of MLB baseballs starts with high-quality materials. Workers carefully cut and stitch the leather to make sure it’s strong. Each ball is then tested for size and weight to ensure it meets rules. We can trust that every ball is the same, which helps players perform their best. This careful process makes sure every baseball is ready for the game.

What Materials Are Used In The Construction Of Official Mlb Baseballs, And Where Are They Sourced From?Official MLB baseballs are made from several materials. The outer cover is made of leather. Inside, there is a cork core surrounded by rubber. Most of the leather comes from cow skin, and the cork is sourced from trees in places like Portugal. These materials help make the baseball strong and fun to play with!

How Do The Regulations And Standards Set By Mlb Influence The Design And Production Of Baseballs?Major League Baseball (MLB) has rules about how baseballs should look and feel. These rules tell companies how to make baseballs the right size and weight. They also say what materials can be used. This way, every baseball used in games is the same, making it fair for all players. So, when you watch a game, you know the baseballs follow strict guidelines!

Are There Any Notable Changes Or Innovations In Baseball Manufacturing Techniques In Recent Years That Have Impacted The Game?Yes, there have been some cool changes in baseball manufacturing lately. Companies are using new materials that make baseballs last longer and fly better. Some balls even have special covers to help players grip them easier. These improvements help us enjoy the game more and make it more exciting!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Specific Facility Is Responsible For Manufacturing Baseballs Used In Major League Baseball (Mlb) Games? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The facility that makes baseballs for Major League Baseball (MLB) is called Rawlings. They are located in Costa Rica. Rawlings makes millions of baseballs for the players every year. Each ball is carefully designed for games. Players trust these baseballs to help them win!”}},{“@type”: “Question”,”name”: “How Does The Production Process Of Mlb Baseballs Ensure Their Quality And Consistency? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The production of MLB baseballs starts with high-quality materials. Workers carefully cut and stitch the leather to make sure it’s strong. Each ball is then tested for size and weight to ensure it meets rules. We can trust that every ball is the same, which helps players perform their best. This careful process makes sure every baseball is ready for the game.”}},{“@type”: “Question”,”name”: “What Materials Are Used In The Construction Of Official Mlb Baseballs, And Where Are They Sourced From? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Official MLB baseballs are made from several materials. The outer cover is made of leather. Inside, there is a cork core surrounded by rubber. Most of the leather comes from cow skin, and the cork is sourced from trees in places like Portugal. These materials help make the baseball strong and fun to play with!”}},{“@type”: “Question”,”name”: “How Do The Regulations And Standards Set By Mlb Influence The Design And Production Of Baseballs? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Major League Baseball (MLB) has rules about how baseballs should look and feel. These rules tell companies how to make baseballs the right size and weight. They also say what materials can be used. This way, every baseball used in games is the same, making it fair for all players. So, when you watch a game, you know the baseballs follow strict guidelines!”}},{“@type”: “Question”,”name”: “Are There Any Notable Changes Or Innovations In Baseball Manufacturing Techniques In Recent Years That Have Impacted The Game? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there have been some cool changes in baseball manufacturing lately. Companies are using new materials that make baseballs last longer and fly better. Some balls even have special covers to help players grip them easier. These improvements help us enjoy the game more and make it more exciting!”}}]}